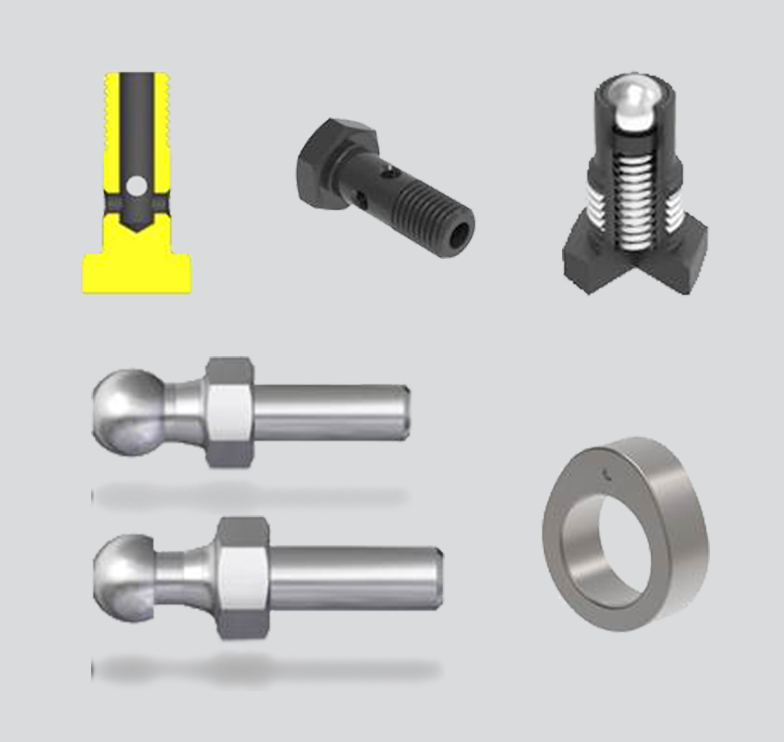

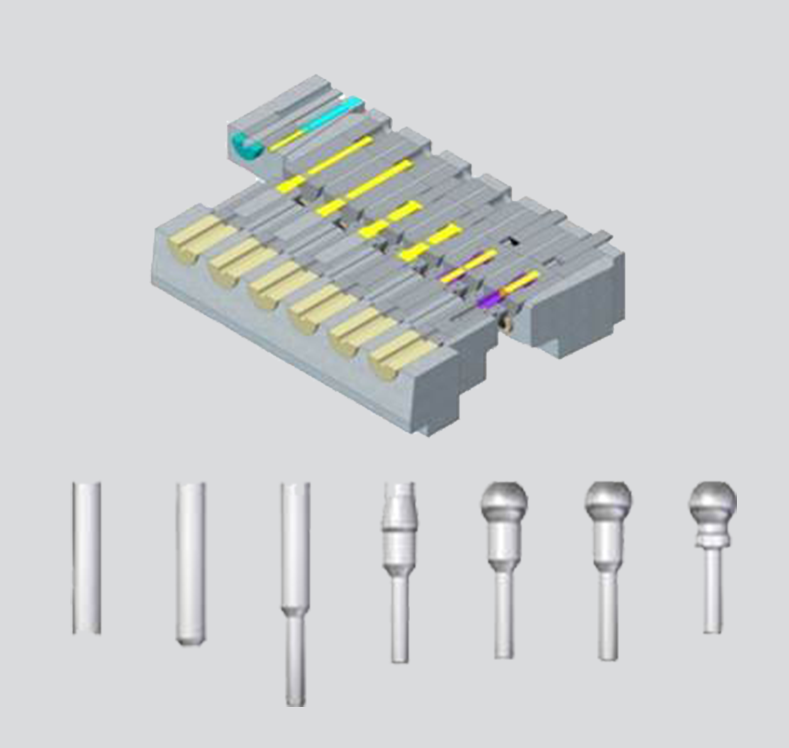

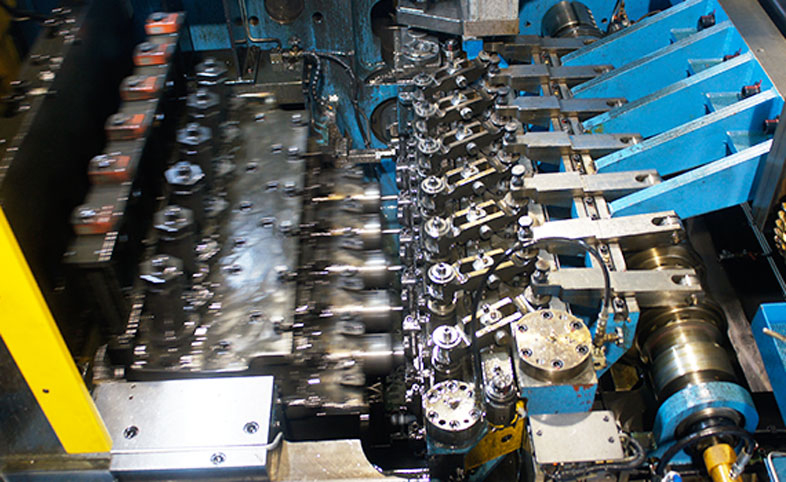

Our horizontal cold-former equipped with optimized dies, automated material feeding & tranfer technologies, offers customers high quality and low cost metal forming solutions.

Piezo-electric sensing technology real-time monitors the forming pressure at each station throughout the entire operation.

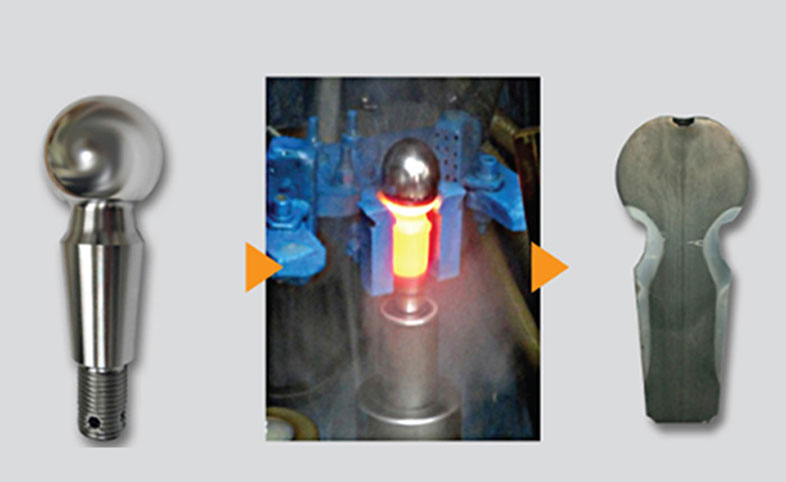

High frequency induction heating technology offers the most economic metal hardening solution optimized for parts that need to be locally hardened. A fully automated process and self error-proofing system assures consistent quality and excellent hardening performance.

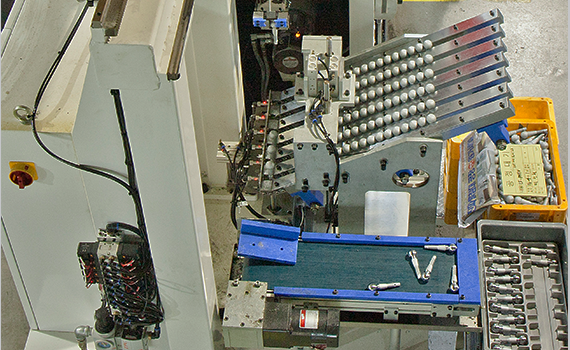

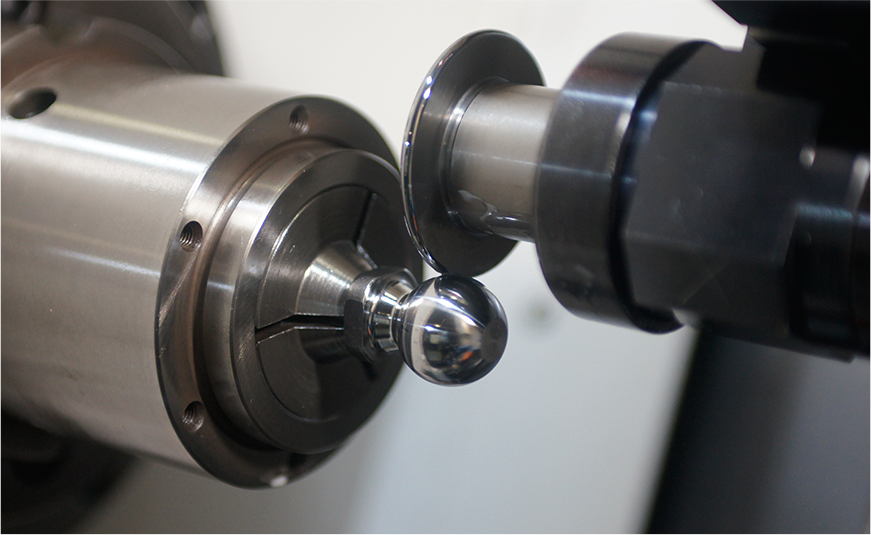

Various capabilities include CNC, drilling, grinding, burnishing, threading and lathe work, Multi-axis CNC with customized and automated sub-devices offers precision and consistency. Exceptional process know-how in hole drilling and burnishing.

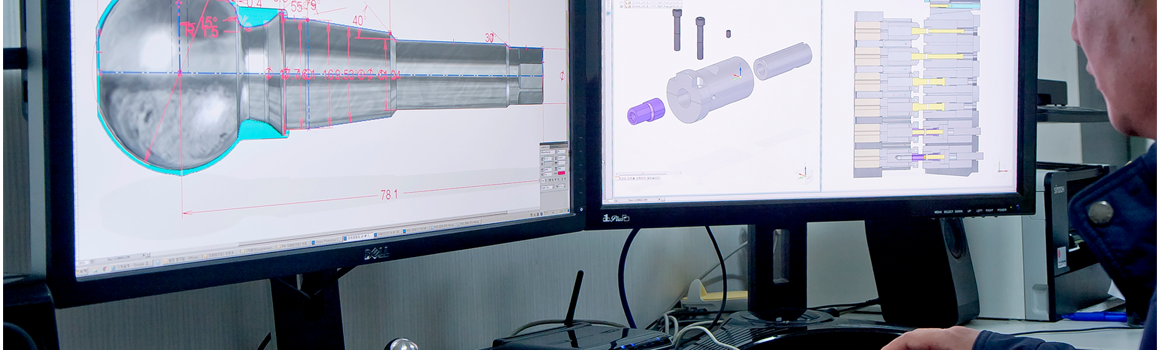

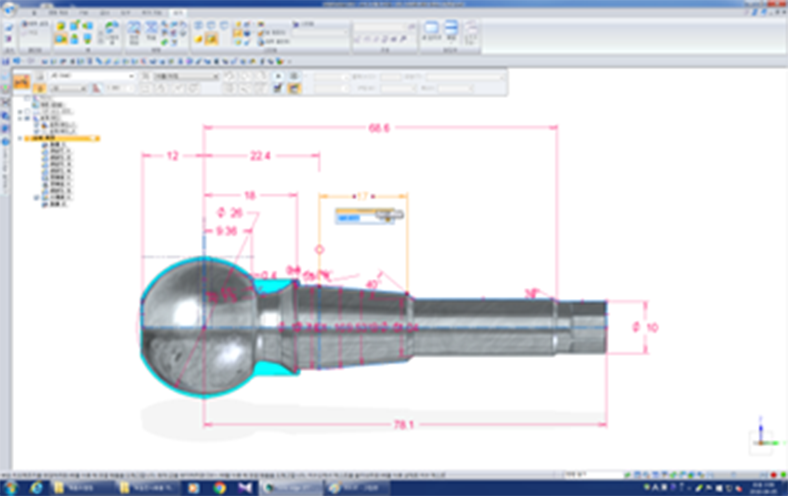

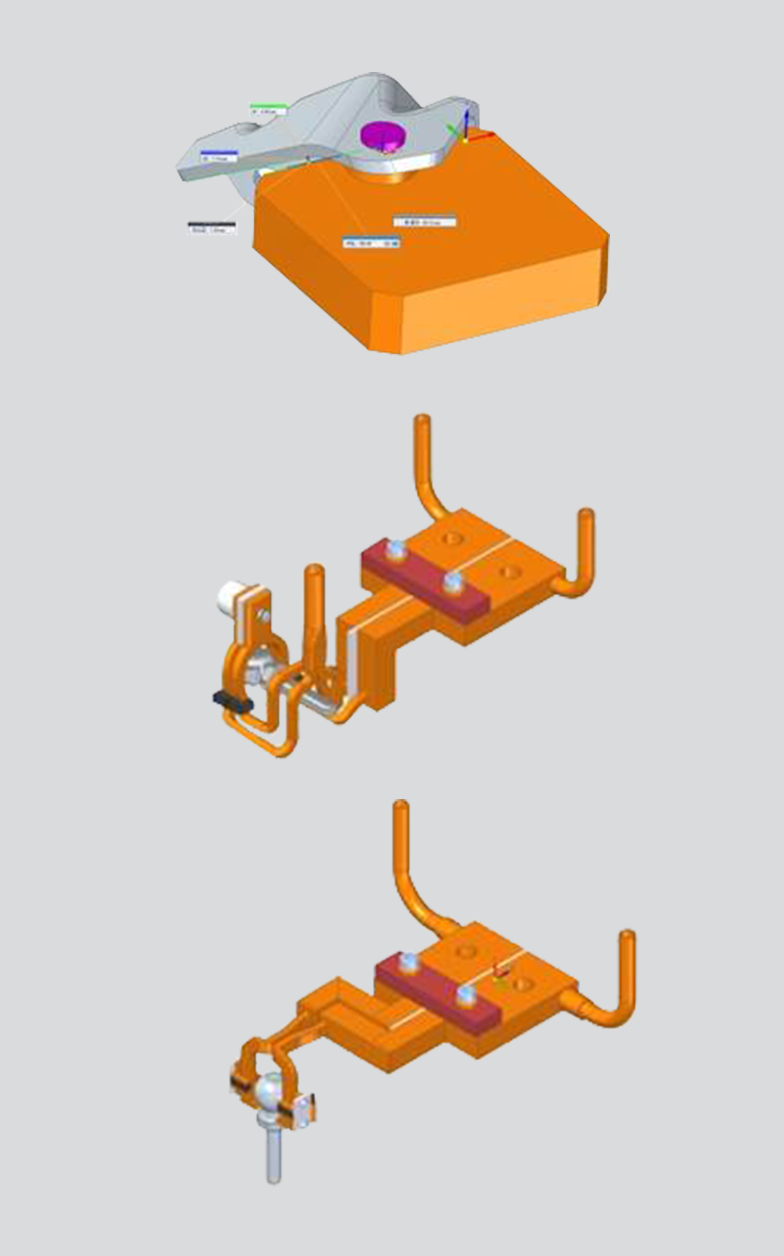

The company is capable of 2D/3D design and simulation to provide reliable production data for product development, tooling and a Jig/Fixture build. The design system is compatible with dwg, dxf, stp, igs, iges formats.